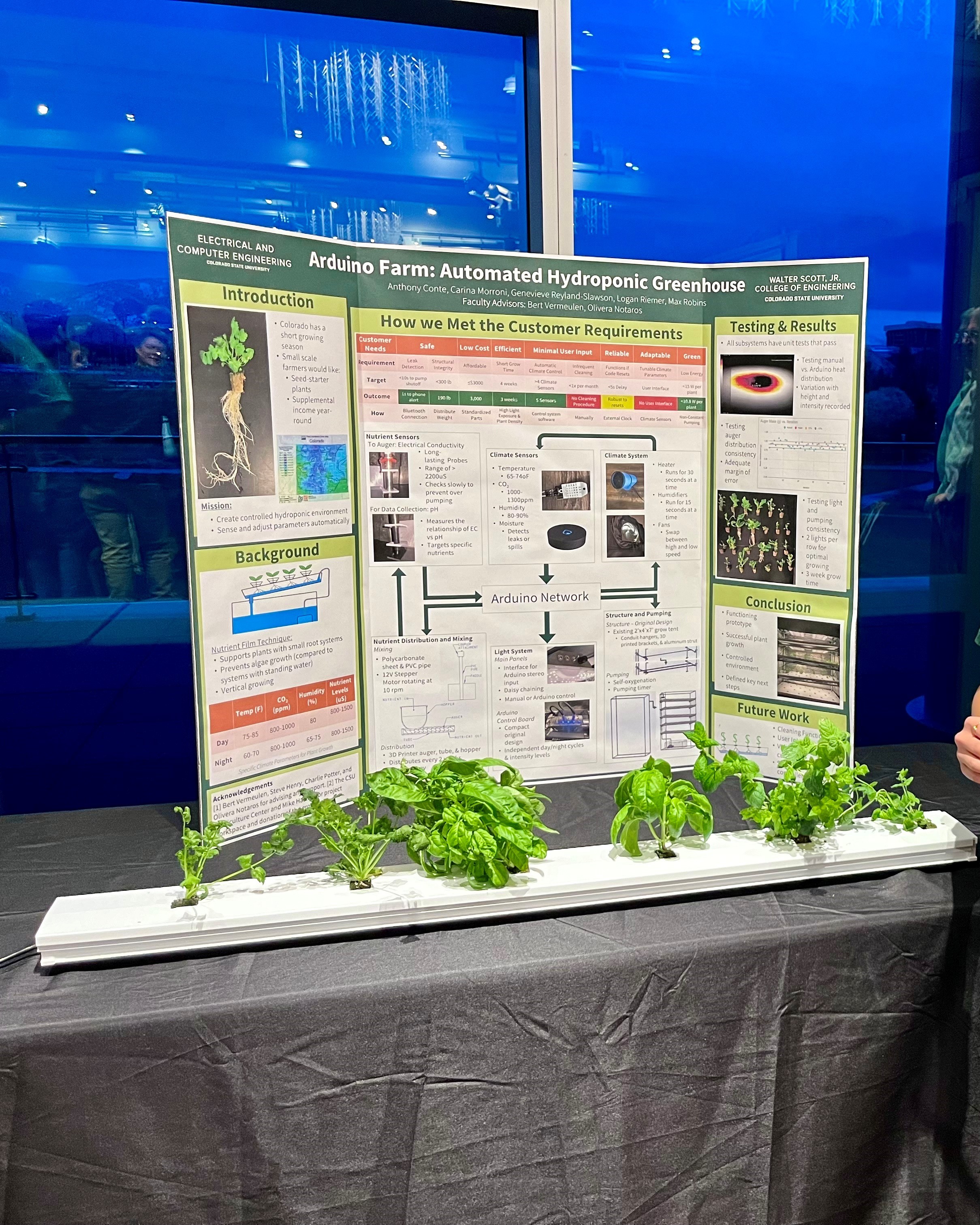

Senior Design Capstone Project

Fully Autonomous Hydroponic Greehouse

This year-long project produced a fully autonomous

hydroponic greenhouse. This greenhouse was a

first year project and was awarded first place at the Senior Design showcase.

This product aimed to address the lack of profit for small scale farmers in Colorado

due to the

short growing season.

This greenhouse can serve as a structure to expedite and streamline the seed

starting process by

autonomously monitoring and maintaining the environment of the closed system through

various sensors

and systems.

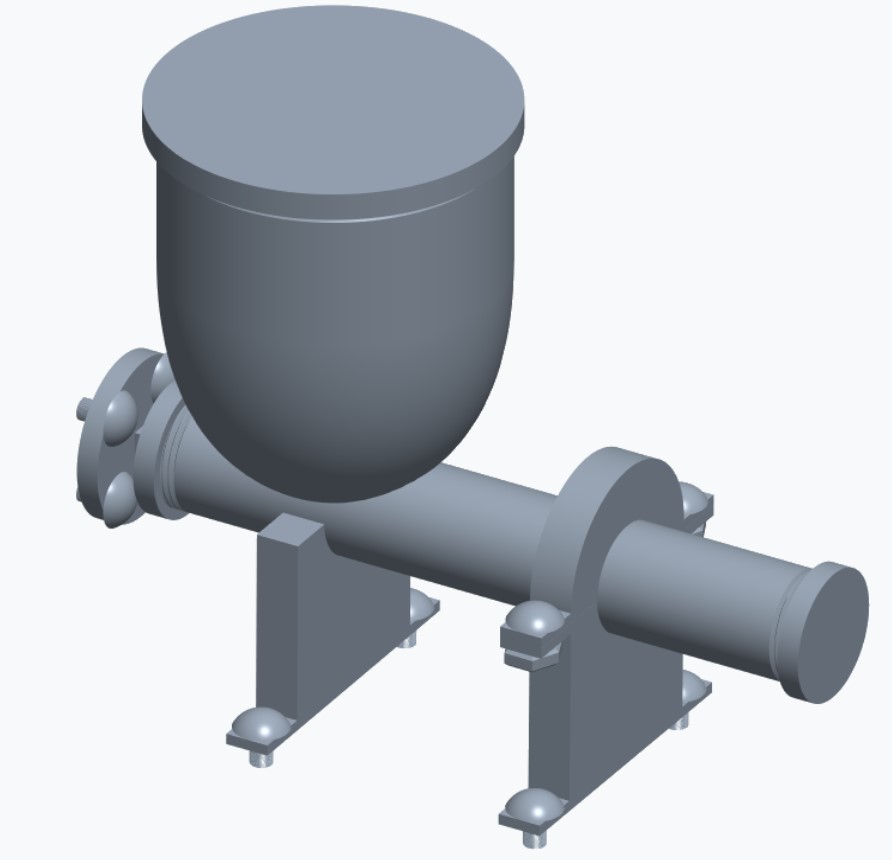

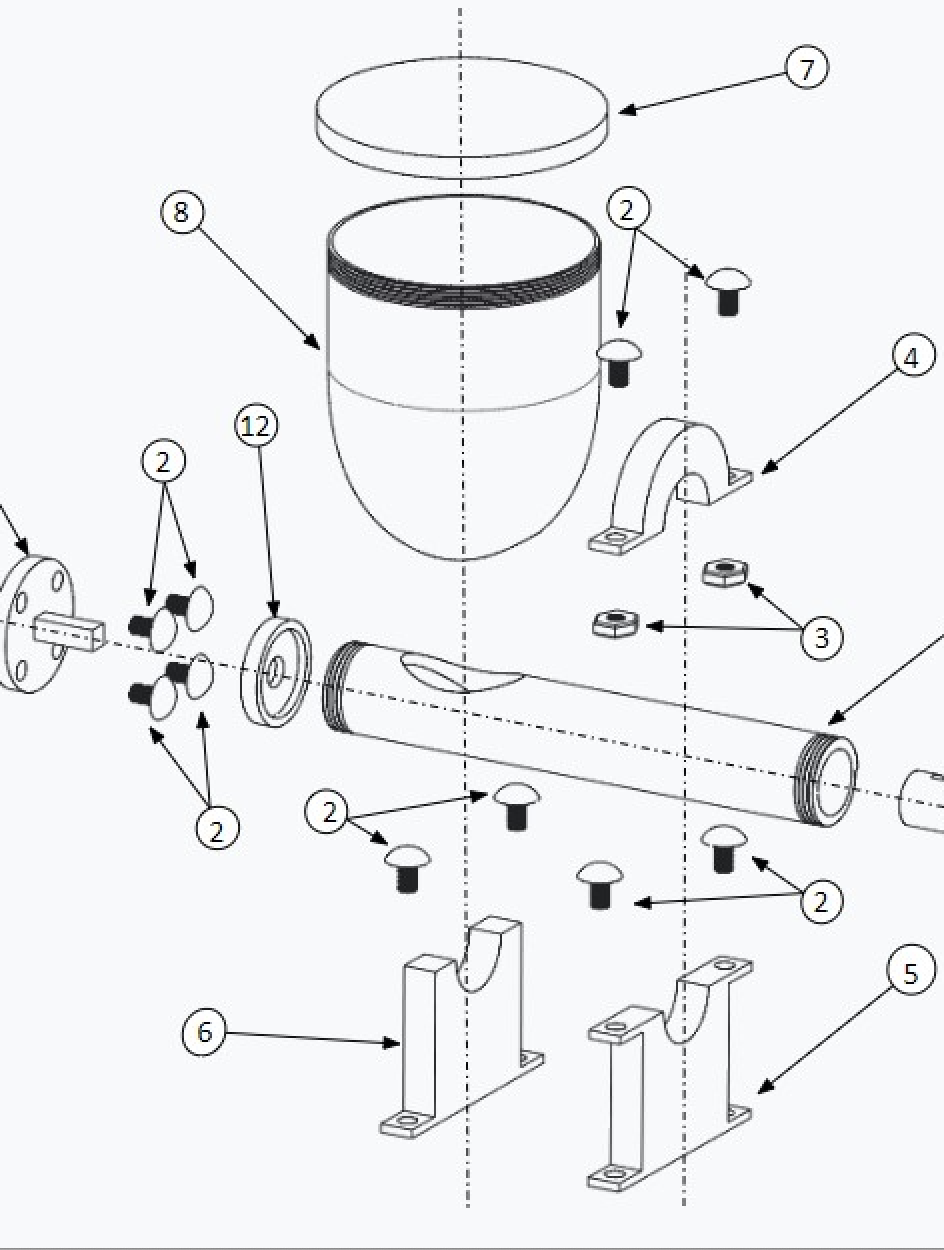

I modeled an original nutrient distribution and mixing system utilizing a hopper to

store dry

nutrients feeding into an auger encompassed by a tube.

In addition, I integrated Arduino stepper motors to both the mixing and auger

systems using

originally developed Arduino code.

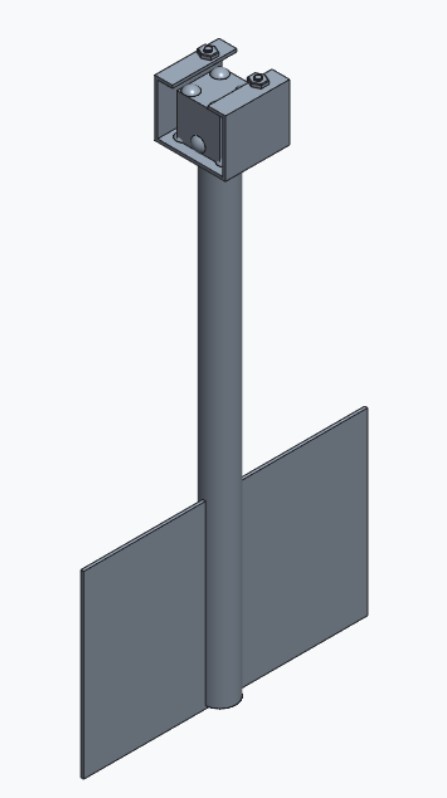

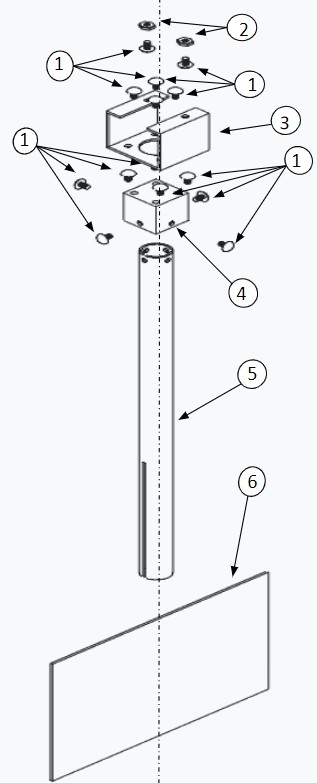

To complete the system, I prototyped supports for the auger to remain stationary

throughout the

distribution process;

the mixer is fixed with a coupler attachment that mounts the mixer and attaches the

motor to the

pipe for constant rotation of the mixer.

For the structure of the greenhouse, it was built from steel bars with dimensions of 4ft x

2ft x

6.5ft. The structure also had a ballistic nylon tent to cover the entirety of the strucutre.

Within

the tent, we purchased hydroponic trays to sit inside the tent on 3D printed brackets and

wer able

to fit 5 rows of trays with 4 trays per row. Water was to be pumped from the base of the

tent to the

top rows of trays, split equally into the four trays, then cycled down the subsequent trays

below.

The entire system had many subsystems that would measure the environment of the greenhouse

then turn

on mechanical systems to maintain an optimal clilmate for the plants. These systems include

sensors

such as: electric conductivity, temperature and humidity, CO2, and pH.